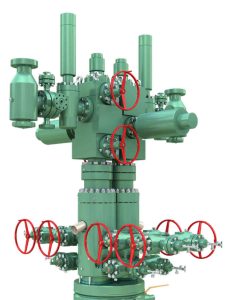

A Christmas tree is an assembly of gate valves, chokes and fittings included with the wellhead during well completion. The Christmas tree provides a means to control the flow of fluids produced from or fluids injected into the well, at surface. While Christmas trees come in a variety of configurations based on a number of well design and operating considerations, typically the bottom connection of the tree matches the top connection of the tubing head adaptor and these are generally installed as a unit, immediately after production tubing is suspended.

Christmas Tree (X-mas tree) is a special mechanical valve assembly which provides service to operator for opening, closing, controlling, and monitoring well stream. Christmas Tree is used for oilfield works, such as hydrocarbons production, enhanced oil recovery, hydraulic fracturing, well testing, and flow back. Configuration of Christmas Tree depends on the requirement of the operator or oilfield Service Company or vendor’s suggestions from serial production.

Below is a basic description of Christmas tree:

Christmas tree is the equipment located above the tubing head. The bottom valve often called the master valve is the primary means for completely shutting in the well. T-type fittings allows for redirection of the vertical flow stream to a horizontal flow line. For a flowing well the produced fluids before entering the surface flow line must pass through the smallest restriction in the surface flow equipment the choke. The choke is used to control the production, perhaps to prevent sand production or to maintain the most efficient rate for the well. The choke restricts the area available for flow through a beam or orifice of a specified diameter that must be inserted into the choke body. The smaller the diameter of the beam the lower the production rate. There are two different kinds of chokes, the positive chokes with interchangeable beans, and adjustable chokes, which allow the choke size to varied more easily. Tubing pressure is measured upstream that is on the wellhead side of the choke by pressure gauge

Christmas tree is the equipment located above the tubing head. The bottom valve often called the master valve is the primary means for completely shutting in the well. T-type fittings allows for redirection of the vertical flow stream to a horizontal flow line. For a flowing well the produced fluids before entering the surface flow line must pass through the smallest restriction in the surface flow equipment the choke. The choke is used to control the production, perhaps to prevent sand production or to maintain the most efficient rate for the well. The choke restricts the area available for flow through a beam or orifice of a specified diameter that must be inserted into the choke body. The smaller the diameter of the beam the lower the production rate. There are two different kinds of chokes, the positive chokes with interchangeable beans, and adjustable chokes, which allow the choke size to varied more easily. Tubing pressure is measured upstream that is on the wellhead side of the choke by pressure gauge.

The choke is used to control the production, perhaps to prevent sand production or to maintain the most efficient rate for the well. The choke restricts the area available for flow through a beam or orifice of a specified diameter that must be inserted into the choke body. The smaller the diameter of the beam the lower the production rate. There are two different kinds of chokes, the positive chokes with interchangeable beans, and adjustable chokes, which allow the choke size to varied more easily.

Positive choke is one kind of chokes with interchangeable beans, used to control the production, perhaps to prevent sand production or to maintain the most efficient rate for the well. The choke restricts the area available for flow through a beam or orifice of a specified diameter that must be inserted into the choke body. The smaller the diameter of the beam the lower the production rate.

Adjustable choke is another kind of chokes, which allow the choke size to vary more easily. As positive choke, adjustable choke is used to control the production, perhaps to prevent sand production or to maintain the most efficient rate for the well. The choke restricts the area available for flow through a beam or orifice of a specified diameter that must be inserted into the choke body. The smaller the diameter of the beam the lower the production rate.

X-MAS Tree Cap

The tree cap bolts to the top of X-MAS Tree and provides quick access to the tubing bore via a nut and plug assembly. It is basically consisting of a Flanged body, Blanking Plug, Nut as principal parts and O-ring as secondary parts. Blanking Plug has a provision to accommodate needle valve and pressure gauge to ascertain inside pressure of the well. They are available in all standard API flange sizes, pressures and trims.

BSP’s X-Mass Tree Cap is designed for below Advantage

- Provides access to the wellhead for service and monitoring.

- The nut fixes the plug in its situation.

- Has hammer nut for easier operation